Plastic Part Decoration

Plastic Part Decoration

lastic parts like those used in almost every consumer product are often left bare—they pop out of the injection mold and are assembled into their final product. This is the most cost-effective means of producing injection-molded parts but restricts them to the color of the bulk material and textures of the mold itself.

View Full PostEmbedded TDD: Breaking the Hardware Dependency

Embedded TDD: Breaking the Hardware Dependency

n a previous blog post I wrote about some of the challenges facing the use of test driven development (TDD) in an embedded environment. It's important to be aware of these obstacles, but also important to keep in mind that all of them are solvable. This post deals with perhaps the most prominent problem (or at least the one I found most daunting originally): hardware dependency.

View Full PostElectromagnetic Compatibility Best Practices

Electromagnetic Compatibility Best Practices

Consumer electronic devices have exploded in popularity in recent years and they have become an integral part of our daily lives. For all these devices to work in harmony, the Federal COmmunications Commission (FCC) has put a great deal of work into creating rules that these devices must abide by. These rules and regulations primarily exist to ensure devices do not emit interference that may degrade or diminish the performance of surrounding devices.

View Full PostThe System Is Down

The System Is Down

Engineering is a field with many areas of specialization, which frequently require engineers from different disciplines to work together to complete projects. For instance, a modern automobile has design input from thousands of mechanical engineers but also contains miles of wiring a

View Full PostFinishing An Injection Molded Part

Finishing An Injection Molded Part

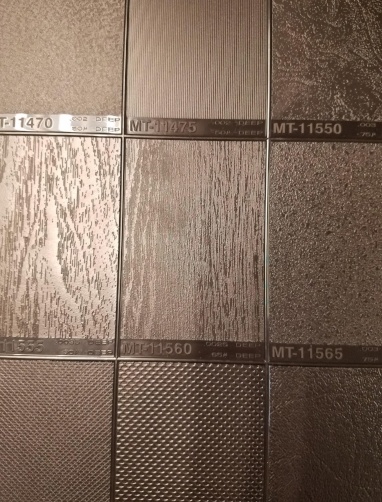

If you look at any of the plastic parts immediately around you, chances are that most of them have been injection molded. Of course, if you’re at a Boulder climbing gym, most of the plastic there is a little different—it’s poured. In any case, you’ll notice that not only do many plastic parts look very different, but they feel very different too. The surfaces and textures on plastic parts may span a large range of common options in the injection molding industry.

View Full PostSabotage 101

Sabotage 101

Hardware design can be difficult, so we try to mitigate any risks or difficulties associated with it as early as and whenever possible. However, we have come across some daredevils out who like to turn the dial up to 11. These are the clients who pepper in extra challenges thinking that the impact will be negligible, but wind up with an inflated budget, blown schedule, reduced sanity, or some combo of the three. Let's see if we can characterize some of the patterns, so you can identify these "saboteurs" in the wild...

View Full PostFood Contact Safe Materials

Food Contact Safe Materials

Food contact materials (FCMs) are all materials and articles intended to come into contact with food, such as packaging and containers, kitchen equipment, cutlery and dishes. These can be made from a variety of materials including plastics, rubber, paper and metal. They also include materials used in processing equipment, such as coffee makers or production machinery as well as containers used for transport.

View Full PostOpen Source Software Licensing

Open Source Software Licensing

Commercial and Proprietary software often include open source components in their system. It can be confusing to understand the legal implications of incorporating them without deeply understanding the license itself.

View Full Post.svg)