The Subtleties of Draft Angles and Injection Molding

The Subtleties of Draft Angles and Injection Molding

View Full PostPlastic Part Decoration

Plastic Part Decoration

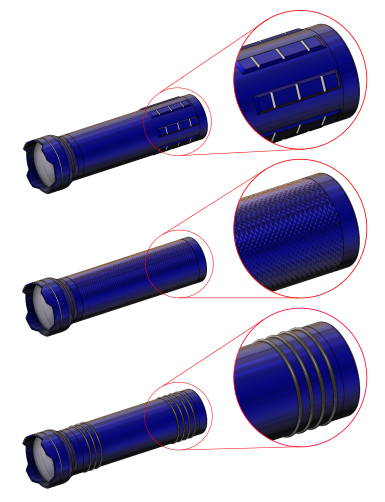

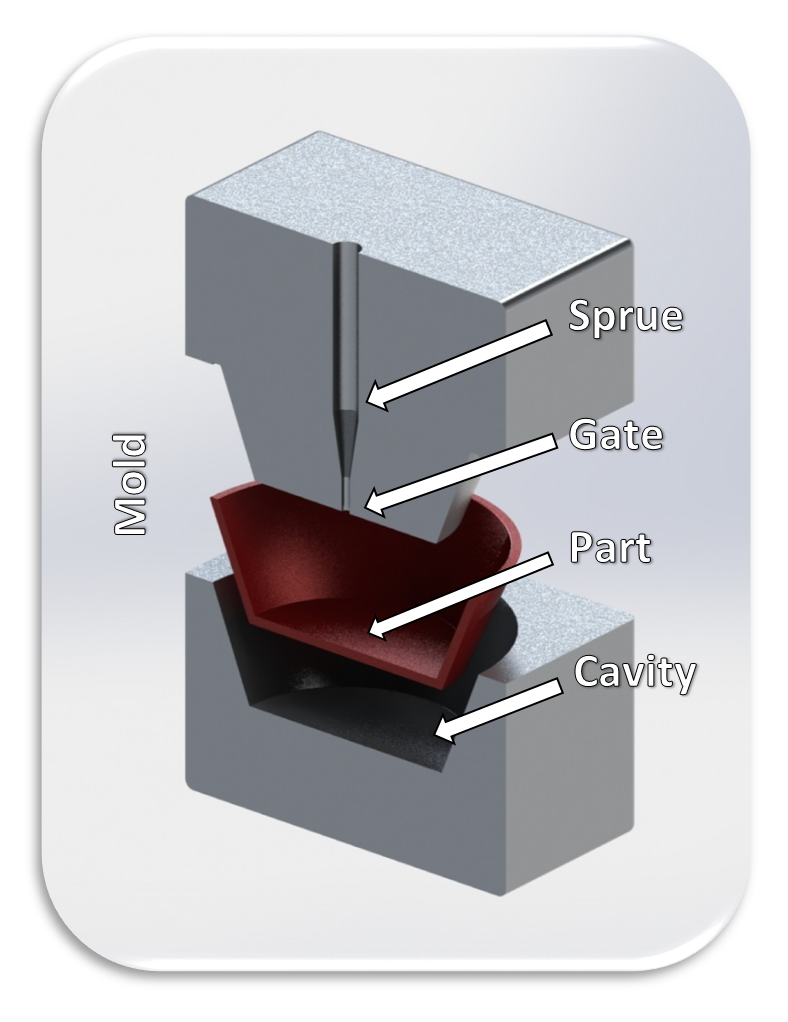

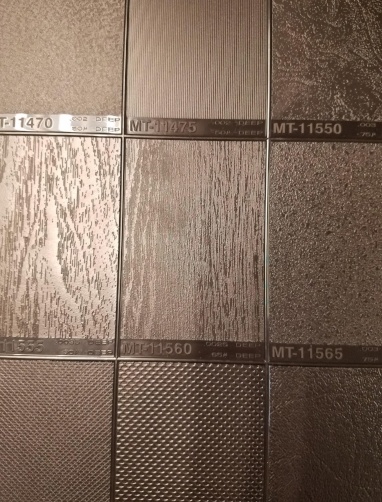

lastic parts like those used in almost every consumer product are often left bare—they pop out of the injection mold and are assembled into their final product. This is the most cost-effective means of producing injection-molded parts but restricts them to the color of the bulk material and textures of the mold itself.

View Full PostFinishing An Injection Molded Part

Finishing An Injection Molded Part

If you look at any of the plastic parts immediately around you, chances are that most of them have been injection molded. Of course, if you’re at a Boulder climbing gym, most of the plastic there is a little different—it’s poured. In any case, you’ll notice that not only do many plastic parts look very different, but they feel very different too. The surfaces and textures on plastic parts may span a large range of common options in the injection molding industry.

View Full Post304 vs 316 Stainless Steel

304 vs 316 Stainless Steel

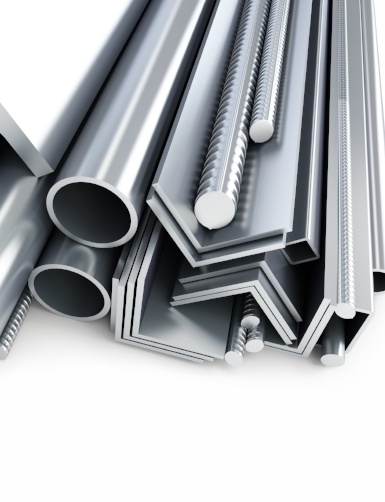

These two Stainless Steels are very similar in their mechanical properties and are among most widely used austenitic stainless steels (304 edging out 316 for most prevalent).

View Full PostWorking With Local Machine Shops

Working With Local Machine Shops

When your design is ready for prototype or production manufacturing, selecting the right manufacturer or chain of manufacturers is critical to being successful. This blog post will hit on a few of the techniques we use when looking at a new machine shop and placing a job there.

View Full Post.svg)